State of the Art Cleanrooms and Procedures

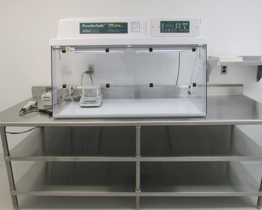

• Brookfield Medical & Surgical Supply cleanrooms utilize ULPA filters which have a greater efficiency than standard HEPA filters.

• Clean room certification performed every six months

• Validated equipment and procedures

• Calibration of autoclave, oven, incubators performed every six months

• Environmental Monitoring

• Viable and non-viable particle counts (air sampling) performed daily under dynamic conditions

• Environmental testing (surface sampling) performed daily under dynamic conditions

• Fingertip sampling is performed at the end of every compounding shift

• Temperature, humidity and pressure differential readings are continuously monitored by an automated system 24 hours a day, seven days a week

• Gowning Procedures

• Sterile coveralls, boots, goggles and hoods are worn

• No exposed skin in the cleanroom

• Gowning procedure validated every six months

• Extensive testing performed on every lot of compounded sterile product (CSP) prior to release- Test results of all lots available upon request

• Sterility tested

• Pyrogen (endotoxin) tested

• Potency tested

• Cleaning Procedures

• Rigorous daily cleanroom cleaning procedures are carried out after completion of compounding shift

• Rotation of cleaning agents including sporicidal agents

• Additional weekly and monthly scheduled cleaning procedures performed